Resources for E-Commerce Business Success

Nabamita Sinha, 6 days ago

As the automotive industry continues to evolve and the global marketplaces remain highly competitive, automakers are increasingly pressured to optimize their supply chain operations.

To efficiently ensure that raw materials, components, and finished products make it into consumers’ hands promptly, digital technology is taking over supply chains.

Companies like Amazon have already been utilizing many aspects within the digitalization of freight management software which has set an example for automakers on how they can improve their processes through modernized methods.

Digital automation of car manufacturing value chain activities has now become essential as it helps create high-quality products while simultaneously keeping costs down and producing them faster than ever before; Thankfully, today’s advances in communication, simulation s supply chain analytics software tools & analytics gives us insight into precisely what a digitally automated automotive supply chain of the future will look like!

The digital automotive supply chain of the future promises to increase efficiency and reduce costs for manufacturers. Automation will help streamline processes, reduce manual labor and eliminate errors caused by human interference.

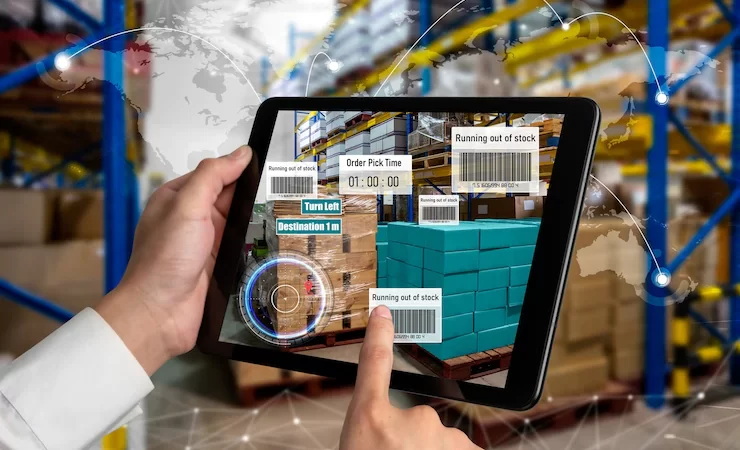

Digital technologies such as AI-driven predictive analytics, blockchain, virtual reality (VR), augmented reality (AR), and data sharing will ensure that products are produced faster and more accurately with minimal waste.

This supply chain management analytics will lead to shorter lead times, improved customer satisfaction levels, decreased overhead costs, and greater flexibility in responding to changing demands.

Additionally, digital tools can facilitate better collaboration between suppliers, giving manufacturers more control over production timelines without sacrificing quality or design features.

Finally, the digital automotive supply chain of the future is expected to enable real-time monitoring of the supply chain, allowing manufacturers to better anticipate and respond to potential disruptions and delays.

With a digital automotive supply chain planning process in place, manufacturers can effectively manage the entire process from design to delivery while ensuring high-quality standards are met.

The advantages of a digital automotive supply chain are clear: increased efficiency, improved customer satisfaction, and significant cost savings. By embracing the new technologies available today, manufacturers can take advantage of these benefits and create a competitive edge in the industry.

With all these advantages in mind, it’s no surprise that more and more companies are beginning to explore how they can use digital solutions to revolutionize their automotive supply chains.

The possibilities for creating an even more efficient, streamlined system are seemingly endless – but only if organizations have the right tools and strategies. It’s time for companies to embrace the digital automotive supply chain of the future and reap the rewards it can bring.

The context of your data is crucial for accurate machine learning forecasting. If you don’t consider the environment in which your data came from, you may get inaccurate predictions.

For example, if you use data from one country to make predictions about another, likely, the results will be insignificant due to differences in cultures and economies.

Likewise, you need to consider seasonal trends or other external factors when predicting future values to ensure you get all the vital information that could impact your forecast.

It’s important to consider all variables when making a prediction model supply chain purchasing to ensure accuracy and reliability.

Data errors can be a big problem regarding machine learning forecasting. You need to consider any data that may have been incorrectly recorded or inputted to ensure your predictions are accurate.

It’s essential to check your data’s quality and ensure it is correct before using it in a machine-learning model. Additionally, it would help if you also looked for outliers and patterns that could throw off your results and considered how you can correct them.

Finally, testing your machine learning forecasting model is essential for ensuring accuracy. You need to be able to assess its performance with historical data before making predictions about future values.

This supply chain risk management strategy means running experiments on different versions of the model to see which performs best. Additionally, you should also test your model’s accuracy over time to ensure it’s still accurate and reliable when given new data. Doing so will help ensure that your predictions are as accurate as possible.

By avoiding these three common mistakes, you can ensure that your machine learning forecasting models are as accurate and reliable as possible. With the proper preparation and care, you can trust the results of your predictions and use them to make better decisions for your business or organization.

The automotive industry is rapidly changing, and the supply chain must keep up. Shortly, we will see more efficient vehicles with improved safety features, a shift towards electric vehicles, an increased focus on sustainability, and smarter systems that will help to reduce costs.

This all means that automotive suppliers must be able to develop innovative solutions that meet these demands while still keeping prices competitive.

As autonomous vehicle technology advances, it could significantly impact the automotive supply chain. Autonomous driving requires advanced technologies such as sensors, cameras, and logistic management software to operate safely and effectively.

Automotive OEMs need to source suppliers who can design and manufacture these components reliably at a reasonable cost. Additionally, autonomous vehicles are expected to increase in popularity, which means that the supply chain must scale quickly to meet the demand.

The emergence of digital technologies in transportation visibility such as blockchain and IoT also has implications for the automotive supply chain.

Blockchain can track materials, parts, and information throughout the supply chain process; this is expected to improve efficiency by reducing paperwork and administrative costs.

IoT devices can monitor inventory levels more closely and help identify potential problems before they arise.

Finally, sustainability is becoming increasingly important in the automotive industry. Automotive suppliers are looking for ways to reduce their environmental impact while still producing high-quality components at a competitive cost. This could include investing in renewable energy sources or using recycled materials in production.

Overall, the automotive supply chain will be drastically different shortly. Automakers and suppliers must be prepared to embrace new technologies, invest in sustainability initiatives, and work together to develop innovative solutions that meet consumer demands. By supply chain consulting services, they will ensure a bright future for the industry as a whole.

Read Also:

Arnab Dey is a passionate blogger who loves to write on different niches like technologies, dating, finance, fashion, travel, and much more.